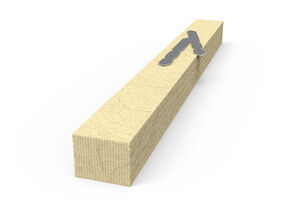

Cavity Barriers

A fully EN tested range of vertical and horizontal, ventilated and non-ventilated cavity barriers for cavities up to 600 mm, offering up to 180 minutes integrity dependent on product and application.

Nullifire’s selection of closed and open state cavity barriers are tested to many construction materials. We offer a huge selection of high performance results, utilising different substrates, different insulation types and a variety of cavity widths and air gaps.

The reactive material within our ventilated cavity products meets and exceeds the requirements of ASFP TGD19, and has been tested and assessed accordingly (certification / assessment can be provided on request).

Ventilated cavity barriers prevent the spread of fire and hot gases through the cavity wall, by sealing off the gap in the cavity when exposed to fire. Keeping the fire contained in a compartmentalized space for the specified period allows people the planned time to evacuate, and permits emergency services to confidently enter the building.

KEY REQUIREMENTS for selecting and specifying a cavity barrier product:

- Determine ventilation requirements of the facade

- If open state, provide required air gap

- Advise us of the internal and external wall construction substrate types

- Confirm insulation type and thickness to be utilised within the cavity

- Qualify maximum width of the cavity (including building tolerances)

- Provide requirements for integrity and insulation performance

- Ensure suitability of internal substrate for stainless steel brackets

- Request horizontal and vertical barriers from the same supplier

- Ask for copies of third-party certifications or assessments.

Specification Services

Offering support in both fire stopping and intumescent coatings, our team works with architects and specifiers to ensure the best possible and most cost-effective solution, without ever compromising on quality and safety of people and the building.

Request Specification Support