How Nullifire FZ400 Enhances Fire-Stopping Seal Longevity | Passive Fire Protection

How Nullifire FZ400 Enhances Fire-Stopping Seal Longevity | Passive Fire Protection

A Technical Insight into Passive Fire Protection

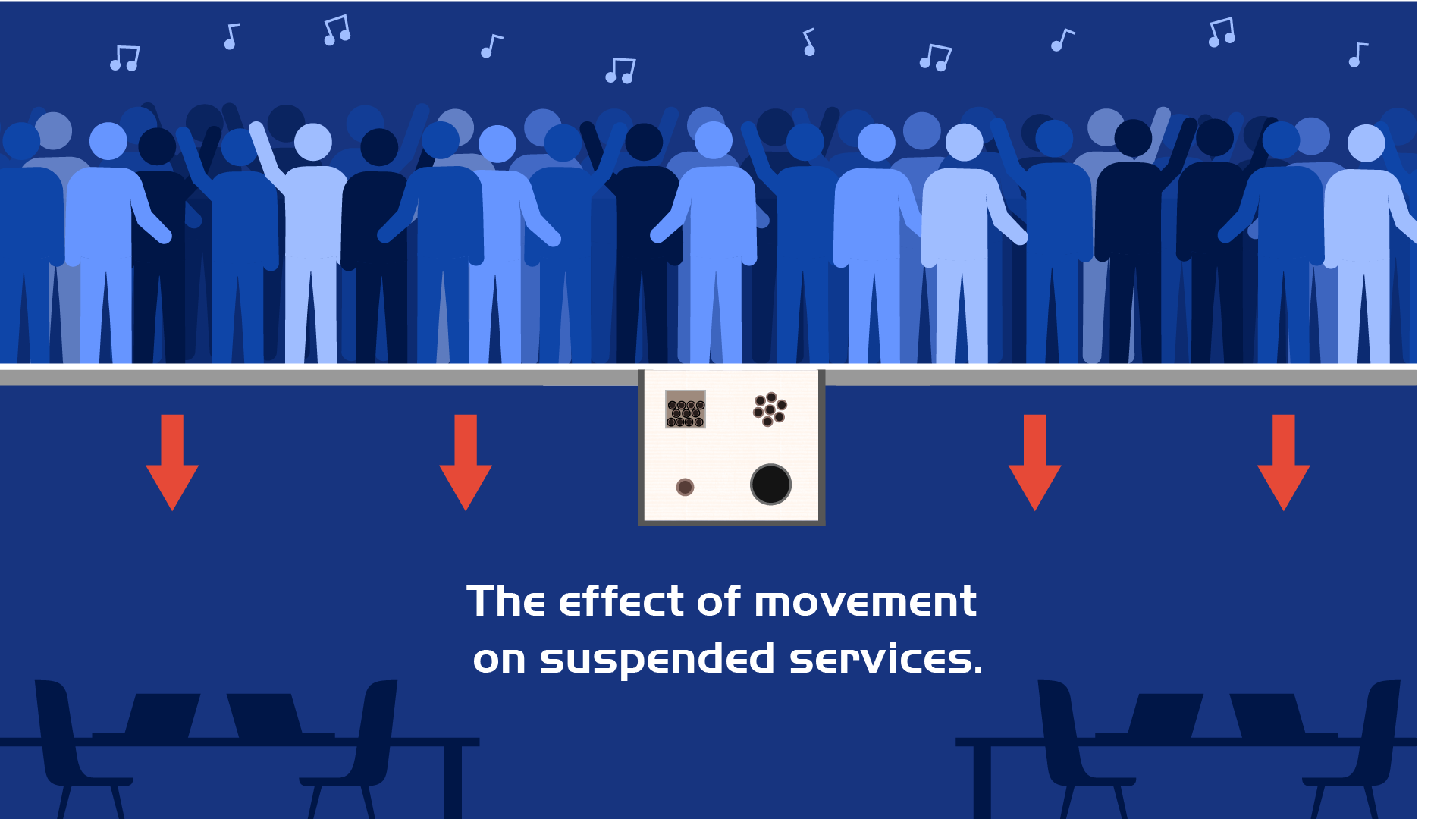

In the realm of passive fire protection, durability is just as vital as fire resistance. Fire-stopping products must not only perform during a fire event but also maintain their structural integrity throughout the building’s lifespan. Factors like joint movement, moisture exposure, temperature fluctuations, and aging can degrade firestop materials over time potentially compromising compartmentation and overall fire safety.

As the industry shifts toward systems that offer both fire performance and long-term resilience, the Nullifire FZ400 movement joint filler has emerged as a standout solution. But does it go beyond sealing dynamic joints? Can it actually enhance the durability of adjacent firestop products?

🔍 Challenges in Firestopping Longevity

Fire-stopping materials including intumescent sealants, insulation wraps, and fire-resistant boards are typically tested under controlled conditions. However, their real-world performance depends on how well they withstand:

- Structural movement: Cracking or displacement from building shifts

- Moisture ingress: Especially in basements or external joints

- Thermal cycling: Expansion and contraction from temperature changes

- Chemical exposure: Sensitivity to cleaning agents or environmental contaminants

In such scenarios, theweakest componentin a firestopping system can undermine the entire assembly. This is where the FZ400’s resilience becomes a strategic advantage.

✅How FZ400 Supports Long-Term Firestopping Performance

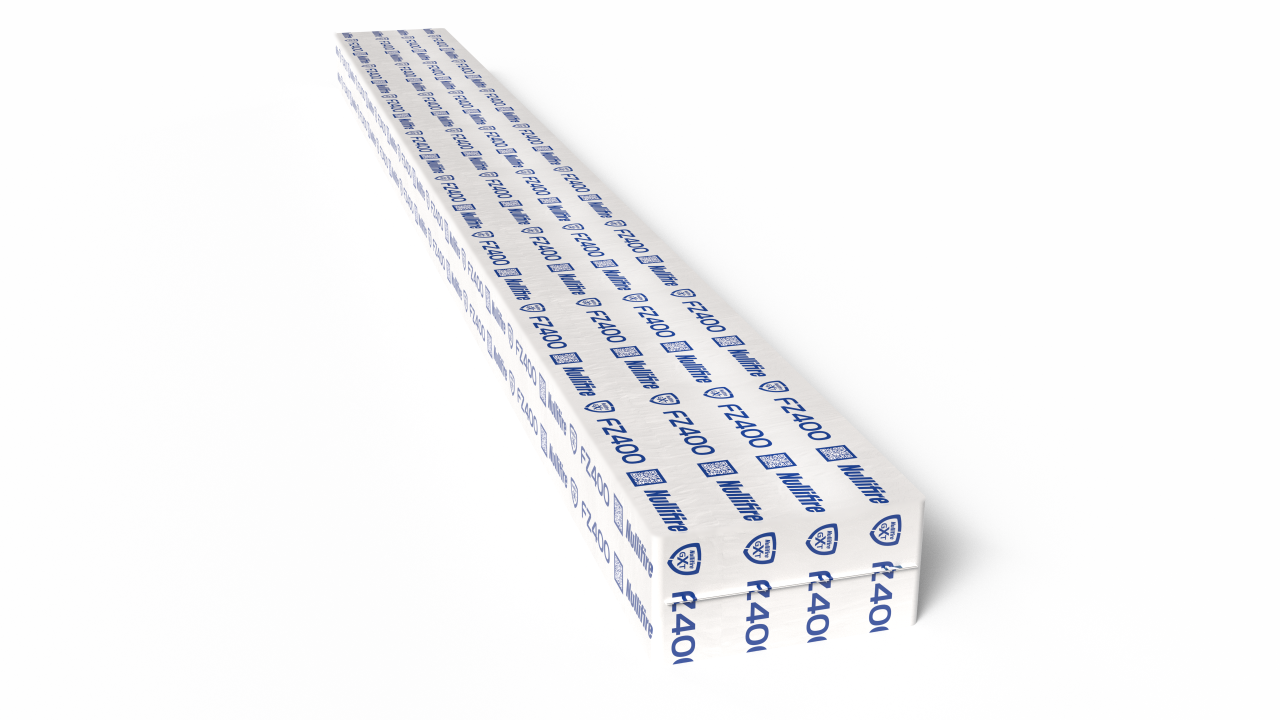

The FZ400 movement joint filler is a flexible, compressible, and fire-resistant material engineered to absorb movement under dynamic conditions. Its role extends beyond joint sealing, actively contributing to the longevity of surrounding firestopping systems.

✅ Key Benefits of FZ400

- Stress Distribution & Load Sharing

FZ400 absorbs and redistributes mechanical stress across the joint. When paired with rigid materials like firestop boards or intumescent sealants, it minimizes fatigue and cracking caused by cyclical movement. - Reduced Maintenance & Inspection Needs

In retrofit applications or hard-to-access areas, FZ400 enhances system reliability potentially reducing the need for frequent inspections or repairs. This translates to lower lifecycle costs and improved safety assurance.

✅Practical Applications

- Multi-product seals: In assemblies combining boards, wraps, and sealants, FZ400 acts as a resilience layer that helps all components perform better over time.

- Seismic joints: In high-movement zones, FZ400 maintains flexibility and protects adjacent firestop materials from stress-induced degradation.

Final Verdict: A Smart Addition to Firestopping Assemblies

While fire resistance ratings remain a top priority, long-term durability is equally critical. The Nullifire FZ400 offers a compelling solution for professionals seeking to extend the lifespan of firestop systems.

By absorbing movement, buffering environmental stress, and preserving seal integrity, FZ400 protects not just the building but the investment in its fire safety infrastructure.