Nullifire’s Patented Firestop Solution Powered by Expanded Graphite

Nullifire’s Patented Firestop Solution Powered by Expanded Graphite

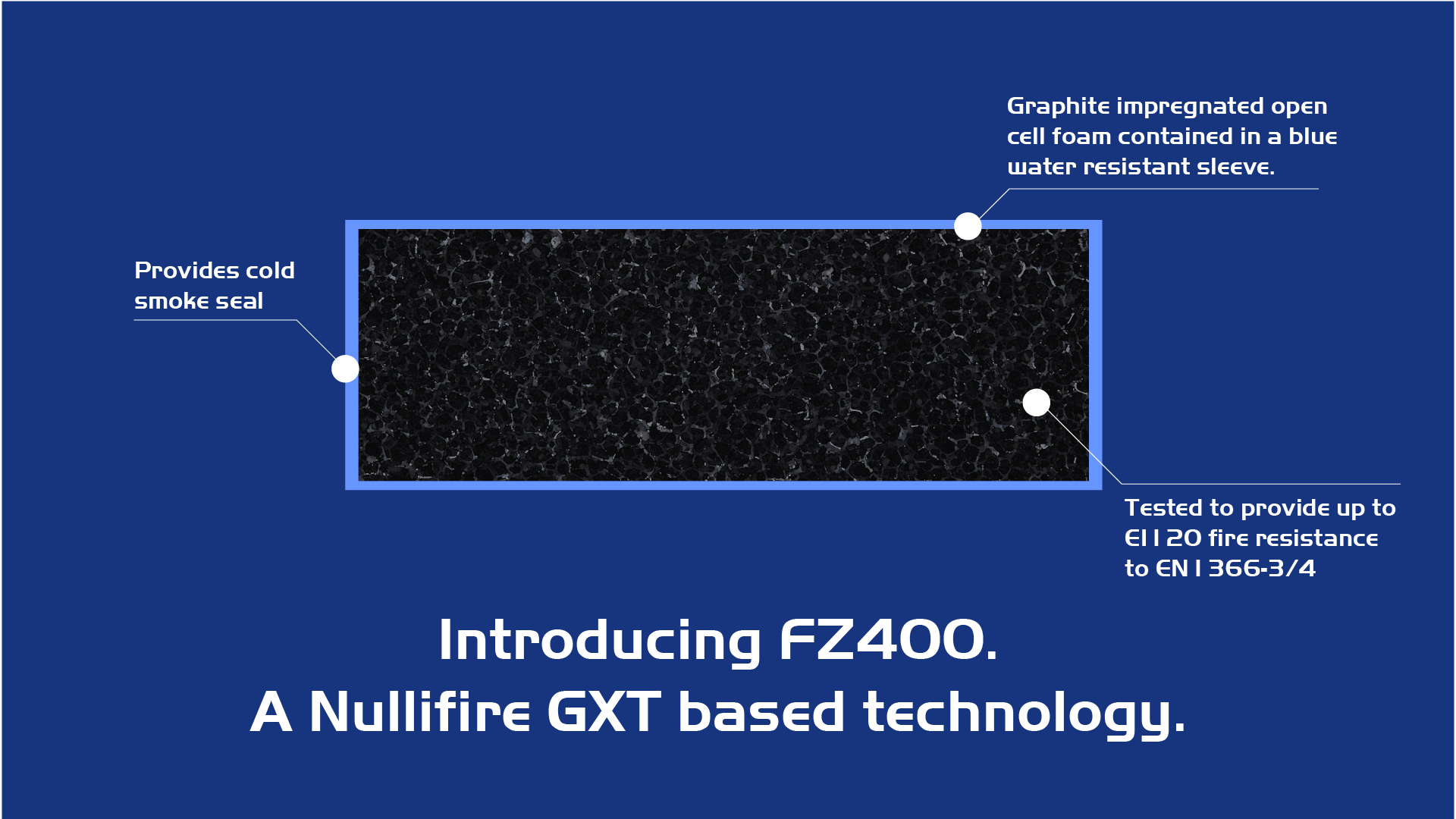

At the heart of some of Nullifire’s most effective firestopping innovations—like the FZ400 movement joint filler—lies an advanced material that transforms under extreme heat: expanded graphite. This high-performance technology plays a crucial role in passive fire protection, enabling Nullifire to create intelligent solutions that react instantly when exposed to fire and protecting buildings and occupants.

✅What Is Expanded Graphite?

Expanded graphite is a high-performance material derived from natural graphite flakes. Through a process calledintercalation, chemical compounds are inserted between graphite layers. When rapidly heated, the flakes expand up to 300 times their original volume, forming a lightweight, worm-like structure ideal for fire protection applications.

✅How Expanded Graphite Enhances Firestopping

In fire scenarios, expanded graphite intumesces swelling to form a dense, insulating char layer. This barrier resists smoke, heat, and flames, making it a critical component in passive fire protection systems. It’s especially effective in sealing:

- Service penetrations

- Electrical cables and ducts

- Movement joints in combustible materials

✅Nullifire’s FZ400: Powered by Expanded Graphite

FZ400 Movement Joint Filler is engineered to deliver up to 120 minutes of fire resistance. When exposed to heat, the embedded expanded graphite activates instantly, expanding to seal gaps and maintain compartmentalization—a key strategy in fire containment.

✅ Key Benefits of Expanded Graphite in Nullifire Products

- Rapid Intumescence: Quickly expands to block fire pathways

- High Thermal Stability: Performs reliably under extreme temperatures

- Flexible & Compressible: Adapts to complex shapes and service configurations

✅Certified Fire Protection You Can Trust

All Nullifire firestopping products, including those with expanded graphite like FZ400, undergo rigorous testing to meet international fire safety standards. This ensures dependable performance in real-world fire conditions providing peace of mind for architects, contractors, and building owners.

✅The Future of Firestopping with Sustainable Materials

As the construction industry shifts toward sustainable, high-performance materials, expanded graphite continues to play a pivotal role in Nullifire’s innovation pipeline. Its unique properties make it ideal for modern fire protection systems