The Importance of Correct Application and Equipment - Intumescent Coatings & Spray-Applied Mortars.

The Importance of Correct Application and Equipment - Intumescent Coatings & Spray-Applied Mortars.

Fire safety in buildings is more than a matter of regulation—it is a matter of life safety. Among the various passive fire protection measures, intumescent coatings and spray-applied mortars play a critical role in protecting structural integrity and ensuring safe evacuation. However, the effectiveness of these systems depends heavily on correct application and the use of the right equipment. Even the most advanced materials will fail if installed improperly. This is why we would strongly recommend the use of a specialist Passive Fire Protection contractor to carry out the work, with 3rd party accreditation in the relevant field to ensure compliance, quality and protection of liability on your project.

1. Why Correct Application Matters

The performance of fire resistant systems is validated through rigorous fire testing in accordance with standards such as BS EN 13381 series, and BS476 Pt 21-22. These test results only hold true when the products are applied exactly as tested and specified by the manufacturer and the approval documentation.

Incorrect application can lead to:

- Loss of certification – Deviating from tested and approved methods invalidates warranties and potentially compliance with building codes.

- Premature structural failure – For steelwork, inadequate intumescent or mortar thickness can lead to faster loss of load-bearing capacity.

- Costly rework – Failed inspections may mean removal and reapplication, but any remediation will only increase project costs and delays.

2. Fire Resistant Intumescent Coatings

Function:

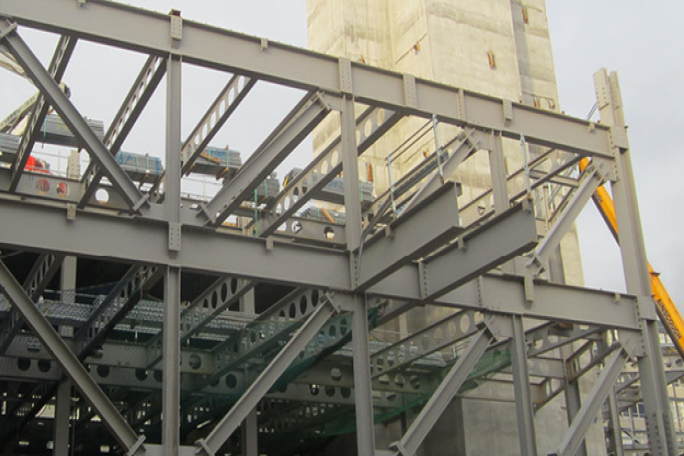

Intumescent coatings expand many times their original thickness when exposed to heat, forming an insulating char layer that slows heat transfer to the underlying substrate—commonly steel beams, columns and tubes. Often used for steel structures that are visible to the building occupants.

Key Application Requirements:

- Surface preparation – Clean, dry, free from oil, rust, and contaminants.

- Correct dry film thickness (DFT) – Measured using a calibrated thickness gauge, according to manufacturer’s fire resistance tables.Thin layers for aesthetic finish

- Application equipment – spray pump and spray tips in good, clean condition so the product can be applied as supplied to allow even, thin coats giving a highly aesthetic finish.

- Environment control – Temperature, humidity, and ventilation must be within specified limits to ensure adhesion and drying or curing.

Essential Equipment for Application:

1. Airless spray machine – For large areas, ensures consistent coverage and smooth finish.

2. Rollers and brushes – For touch-ups, edges, and hard-to-reach areas.

3. Wet film thickness gauge – To check applied thickness before curing.

4. Dry film thickness (DFT) gauge – For final verification and progress along the way.

5. Mixing equipment – Mechanical stirrers to ensure product is homogenous.

6. Personal protective equipment (PPE) – Respirators, gloves, goggles, and protective clothing.

3. Spray-Applied Mortars

Function:

Spray-applied mortars provide a robust, uniform layer of passive fire protection, typically used for long protection times of steel structures against fire. Often used for steel structures that are hidden from the building occupants.

Key Application Requirements:

- Surface priming – Some substrates require bonding agents to enhance adhesion or mesh.

- Correct thickness and density – Verified with pin gauges or depth checks, as mortar fire resistance depends on both.

- Even coverage – Avoiding thin spots or overspray build-up.

- Curing control – Protection from rapid drying or excessive moisture during curing.

Essential Equipment for Application:

1. Pneumatic or hydraulic mortar spray machine – With hopper and pump to feed the material. Can be continuous or discontinuous supply.

2. Compressor – Adequate CFM to drive the spray gun.

3. Spray gun with adjustable nozzles – For controlling spray pattern and thickness.

4. Hand trowels – For smoothing and finishing details around penetrations, corners and edges.

5. Pin depth gauges – For measuring applied thickness at multiple points.

6. Mixing paddles and drums – To prepare mortar to the correct consistency.

7. PPE – Respiratory masks, gloves, and coveralls due to dust generation.

8. Clean potable water supply.

4. Quality Control and Inspection

Regardless of the product type, quality control is essential to ensure fire stopping systems perform as intended. This includes:

- Recording environmental conditions during application.

- Checking each layer for defects or missed spots.

- Documenting thickness measurements for compliance.

- Following manufacturer’s installation instructions exactly.

Conclusion

The correct application of intumescent coatings and spray-applied mortars is not just a technical matter—it is a life safety issue. The right equipment, skilled operators, and strict adherence to manufacturer’s guidelines are crucial for ensuring the fire resistance performance seen in laboratory testing is replicated on-site.

A shortcut taken in application today could mean a catastrophic failure tomorrow.

Comparison: Intumescent Coatings vs Spray-Applied Mortars

Feature | Intumescent Coatings | Spray-Applied Mortars |

Primary Function | Expands under heat to form an insulating char, protecting structural steel, , concrete or other metallic substrates. | Maintains a thick, insulating layer, protecting structural steel, , concrete or other metallic substrates. |

Typical Applications | Structural steel beams, columns, pipes and concrete. | Structural steel beams, columns, pipes and concrete. |

Surface Preparation | Requires clean, dry, and primed surfaces; rust removal for steel. | May require bonding agent; surface must be free of loose debris. |

Application Method | Sprayed with airless spray machine; can be brushed or rolled in smaller areas. | Sprayed using pneumatic/hydraulic mortar pump with compressor; finished with trowels. |

Thickness | Thin film coatings for aesthetic finish | Usually applied in one or two thicker layers to achieve required depth. |

Thickness Measurement | Wet film thickness gauge (during application) and dry film thickness gauge (after curing). | Pin depth gauge or physical depth checks at multiple points. |

Key Equipment | Airless spray machine, rollers/brushes, mixing drill, DFT gauges, PPE. | Mortar spray machine, compressor, spray gun, mixing paddles, pin gauges, PPE. |

Finish Appearance | Smooth or slightly textured decorative finish possible. | Rough, textured finish unless smoothed with trowel. |

Environmental Sensitivity | Sensitive to humidity, temperature, and ventilation during curing. | Sensitive to drying conditions; must be protected from rain and rapid drying. |

Advantages | Lightweight, aesthetic finish, flexible application. Allows use of complex steel structures with full protection. | High durability, robust coverage, good for irregular surfaces. High durations of proven fire protection. Reduced cost of installation. |

Limitations | Sensitive to weather during application. | Heavier load on substrate; less decorative finish. |

|

Our technical support is always on hand to answer any questions - contact coatingshelp@tremcocpg.com