Nullifire Advice with Integrity – Sealant Application

Precision in sealant application is paramount for effective seals and joints. In construction and various industries, inadequate or excessive sealant can compromise structural integrity, aesthetics, and lead to performance issues. This article underscores the critical importance of applying the right quantity of sealant for optimal results, emphasising its impact on durability, cost-efficiency, and overall project quality.

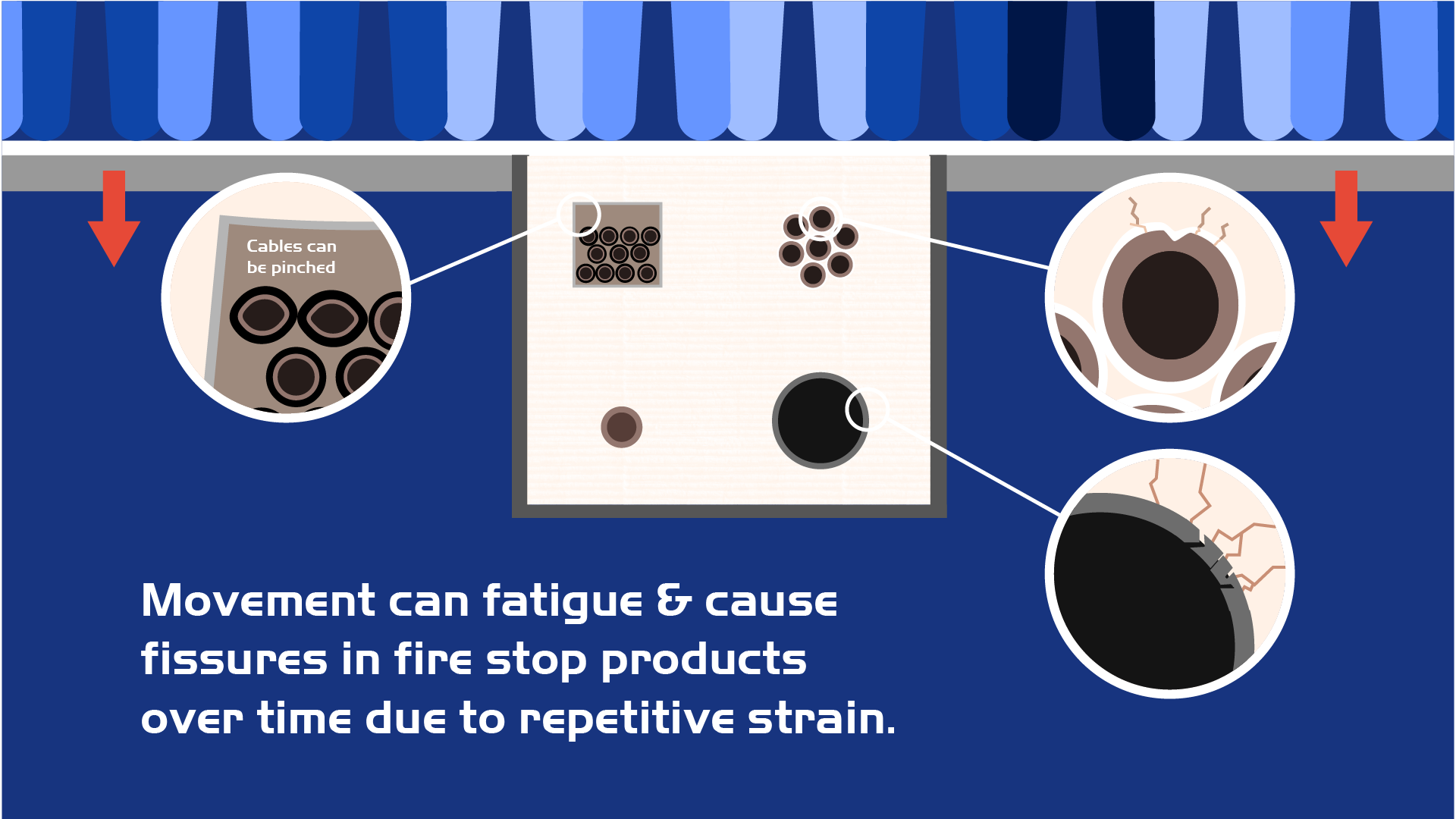

For Movement Joints this should be as tested. Too much and the joint will be too rigid to use and too little, the joint may have insufficient strength to accommodate the movement it is being subjected to. Equally too little may cause surface cracking.

These are reactive products primarily for use around combustible elements maintaining compartment walls.

Sealant depths and annulus should be as per test or slightly greater than tested. There will be limitations to the maximum size tested, and this may be governed by blank seal testing.

Unless a full fill of sealant, front to back is stated, a backing control material must be used.

If an installation detail shows and/or states no backer required, this means that no accurate measurement has been taken during testing. It would be impossible for the correct depth to be known, or to be applied, therefore certification should equally not be possible for that product. In this case, we would assume such issued certification to be poorly considered.

Some backing materials are interchangeable and some are not. It is prudent to conform to certification or manufacturer’s instructions, which should be ratified by the relevant testing standard or related Exap.

- Primers

Primers are occasionally required on extremely porous or excessively shiny surfaces. Again, we would recommend consulting with the manufacturer. Sealants must always be tooled to promote wet out of the sealant, to the surface of the substrate.

In summary, these are our main tips:

- Apply a correct and suitable backer

- Install sealant to a known, correct and a tested depth to width or annulus

- DO NOT accept evidence which states No Backer Required, unless full fill is required through the substrate.

For further details on tested service Integrity and Insulation requirements or results, please contact our Technical team via firestoppinghelp@tremcocpg.com or on 01942 251 400. They will always give you Answers with Integrity.