What is the difference between Reaction to Fire and Resistance to Fire?

Whether you’re a contractor, engineer, architect, or simply someone looking to find out more information on the subject, the two terms can often be confusing. There is, however, an important distinction between the two.

Reaction to fire evaluates specific materials contributing to fire, whereas resistance to fire assesses a systems ability to resist the penetration through the system or products and prevent temperature rise between the exposed and unexposed sides in a fully developed sire situation.

Reaction to Fire:

As the name suggests, a materials reaction to fire is an indication of how it responds to fire – whether it flares or contributes to the spread of fire.

Reaction to fire testing evaluates a construction materials contribution to fire, predominantly in the early stages of a fire starting. Materials and products can be classified into 7 different Euroclasses according to the way that they react to fire. According to the European standard EN 13501-1, by this standard products belong to one of the seven primary classes (below) according to their level of combustibility, as well as possibly belonging to additional classes according to the amount of smoke developed (s1,s2 or s3) or the amount of burning droplets or particles (d0,d1 or d2).

- A1 – it does not fuel or contribute to the fire

- A2 – little fuel and very low contribution to the fire, without causing flashover

- B – little fuel and very low contribution to the fire, but they cause flashover

- C – Fuel, causes flashover at ten minutes

- D – Fuel, causes flashover before ten minutes

- E – Fuel, causes flashover before two minutes

- F – Indeterminate behaviour, materials and products untested

S – Smoke Opacity.

The ability of the product to not produce flames. It’s divided into:

- S1 – low opacity and smoke production

- S2 – medium opacity and smoke production

- S3 – high opacity and smoke production

D – Flaming Droplets/Particles.

The products ability to produce neither droplets or inflamed particles. It’s divided into:

- D0 – produces drops or particles

- D1 – produces drops and/or non-inflamed particles

- D2 – produces drops and/or inflamed particles

Resistance to Fire:

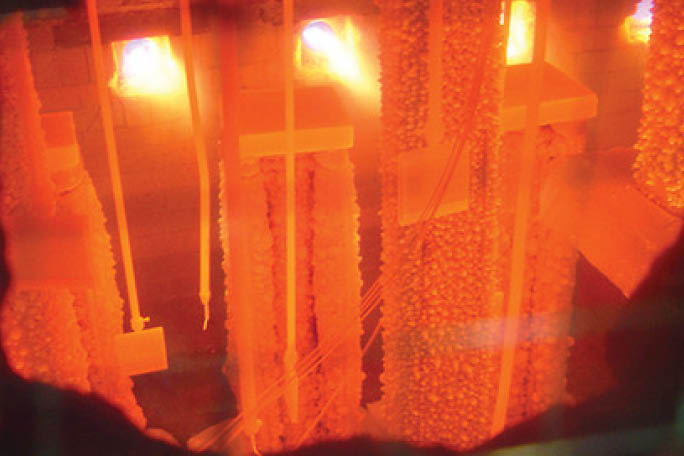

A products resistance to fire measures how well it performs in containing the fire, preventing it from spreading elsewhere. Whilst reaction to fire properties are critical in the early stages of a fire breaking out, resistance to fire rating become critical once the fire has grown and fully developed, since at this stage the products in question are required to contain the fire within the specified locations as per the building compartmentalisation strategy.

Resistance to fire is measured according to three criteria.

- R – Supporting Capacity.

This looks at the capacity of the constructive element to resist mechanically without losing its structural properties.

- E – Integrity.

Capacity of the product to prevent the passage of fire and hot gases into an area not affected by the fire

- I – Insulation.

Capacity of the product to prevent the temperature increase in the face not directly exposed to the fire.

The R, E and I of a product are indicated as a duration. Whether the product can resist fire and prevent it from spreading to the opposing side for 30,60,90 or 120 minutes.